Could cultured meat be available in your U.S. grocery store in the new year? A previous article focused on the topic of “cultured meat” – meat made from the cells of animals and grown in a nutrient medium. While no cultured meat has yet been approved for sale in the U.S., companies are positioning themselves for mass production once needed approvals, licensing, inspections, etc., are obtained.

Earlier this month, Believer Meats broke ground on a $123 million plus facility in Wilson, North Carolina. The facility will be able to produce 10 metric tons of meat a year and will be the largest cultured meat facility in the world. The new facility will be Believer Meats’ second production facility. Last year it opened its first facility in Rehovot, Israel, with the capacity to make 500 kilograms of cultured meat a day. Believer Meats has developed processes to create cultured chicken, beef, pork, and lamb.

Investment in the cultured meat industry has been massive. For example, Believer Meats has $600 million in funding, and its investors include ADM Ventures, part of Archer-Daniels-Midland Co., and Tyson Foods.

Investment in the cultured meat industry has been massive.

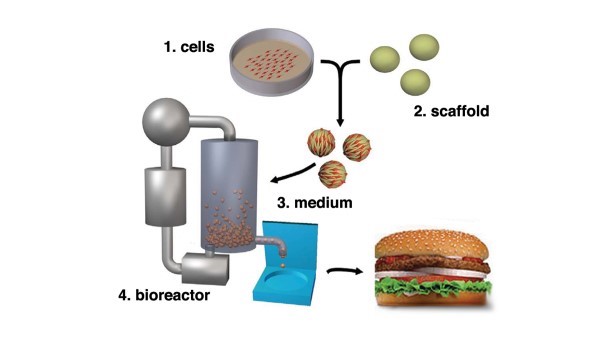

So, with all of the investment and building of facilities, is the sale of cultured meat in the U.S. imminent? Cultured meat was first introduced in 2013. The eventual sale of cultured meat in the U.S. seems inevitable, but the timing is not yet clear. Before any cultured meat can be sold in the U.S., the FDA and USDA must approve the processes, license the facilities, inspect the facilities, inspect the meat, and approve labeling for the meat. Recognizing the rapid development of cultured meat products, the FDA established a premarket consultation process for companies to work with the FDA to start the process of regulatory approval for their cultured meat products. This premarket consultation process permits the companies to, voluntarily, work with the FDA, and to share information about their processes. The FDA premarket consultation does not, itself, “approve” the products, but evaluates the information shared by the companies – in order to determine if the meat is safe for human consumption. Specifically, as part of the premarket consultation, the FDA considers the cells used to make the cultured meat, the processes and materials used to create the cultured meat, and the manufacturing controls under which the cultured meat is created.

Recently, UPSIDE Food Inc. became the first cultured meat company to complete the FDA’s premarket consultation process. In November of this year, the FDA issued a No Questions letter to UPSIDE Food Inc. for its cultured chicken. The letter stated that information provided by UPSIDE Food Inc. to the FDA demonstrated that UPSIDE Food Inc.’s cultured chicken is safe and its production process prevents the introduction of contaminants that would adulterate the product. Last year, UPSIDE Food Inc opened a facility in Emeryville, California capable of producing 50,000 pounds of meat per year.

UPSIDE Food Inc.’s No Questions letter from the FDA is just the first step in the regulatory process. Pursuant to a 2019 agreement between the FDA and USDA, the FDA and the USDA will share oversight of the production of cultured meat. In addition to the premarket consultation, FDA will oversee the creation of the cultured meat up until the time of harvest, including licensing facilities, and inspecting the creation of the cultured meat. Inspections will ensure approved processes are being used and that the cultured cells are grown in a fashion that complies with Good Manufacturing Processes and food safety regulations.

When the cultured meat is harvested and processed into its final form, regulatory oversight will shift to the Food Safety Inspection Service (FSIS) of the USDA. As with traditional meat producers, cultured meat producers will have to apply for Grants of Inspection and be subject to similar inspections and food safety requirements. Labels for the cultured meat will also have to be preapproved by FSIS.

Before Believer Meats can sell any of its products manufactured in the North Carolina facility, Believer Meats will have to navigate the regulatory hurdles necessary to obtain approval of its products for sale to consumers. Believer Meats has indicated that it has been working with the FDA, but the FDA has not yet issued any statement on Believer Meats’ processes or products. However, with the start of construction on the world’s largest cultured meat facility, Believer Meats will be well-positioned to begin commercial production when regulatory approvals are obtained. We will be following this emerging new market and the regulatory rubric designed to oversee these cutting-edge food products.